Towards Smarter and More Sustainable Food Production

Digitalisation is transforming this industry with technologies such as IoT, AI and blockchain, optimising production, enhancing transparency and reducing waste. Companies worldwide are already reaping the benefits of these innovations.The aroma of a traditional bakery blends with the hum of robots kneading dough with millimetre precision. In bottling plants, microscopic sensors detect impurities invisible to the human eye. Meanwhile, in the fields, drones glide overhead, monitoring the growth of each plant and detecting potential pests before they emerge.

The food industry, one of humanity’s oldest, is undergoing a digital metamorphosis that is redefining every stage of the value chain.

Digital transformation is no longer a passing trend but an essential necessity in a world where consumers increasingly demand transparency, sustainability, and efficiency. Companies that fail to adapt to this new reality risk being left behind in an ever-more competitive and regulated market.

The Key to Innovation

The technological revolution in the food sector is being driven by a range of innovations transforming the entire value chain.

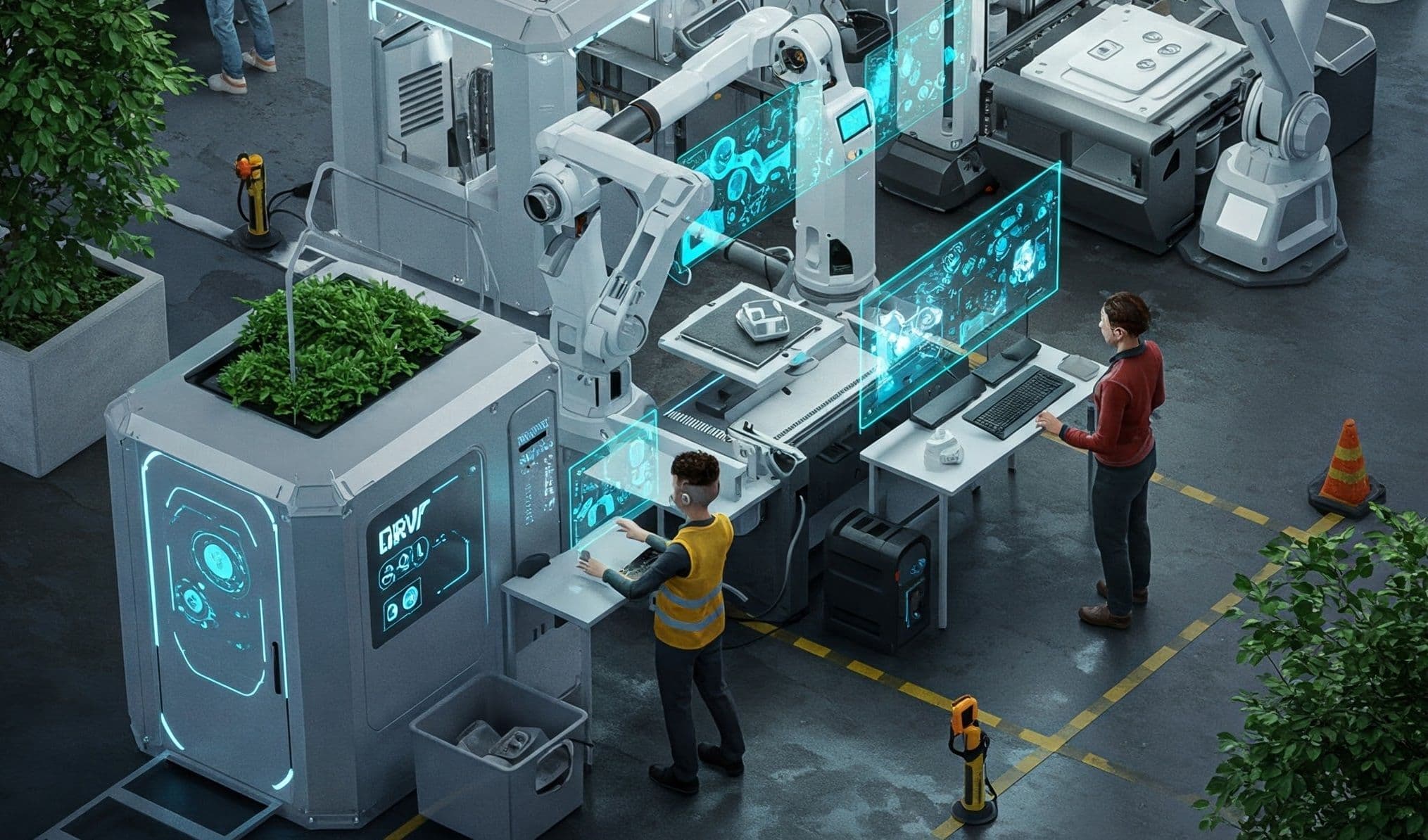

The Internet of Things (IoT) has enabled seamless connectivity across every link in this chain, with devices monitoring production, storage, and transport conditions in real time. Sensors measuring temperature, humidity, and gas levels help ensure food quality and safety, significantly reducing waste in warehouses and cold storage by alerting operators to any deviation from optimal conditions.

At the same time, artificial intelligence (AI) is revolutionising production planning, quality control, and consumer trend forecasting. Advanced algorithms analyse vast amounts of data to predict market demands with remarkable accuracy, while computer vision systems inspect each product on the production line, identifying defects imperceptible to the human eye.

Blockchain technology has introduced an unprecedented level of transparency, allowing every product to be traced from its origin to the final consumer. Simple QR codes on packaging give consumers instant access to detailed information about ingredient origins, production methods, and certifications, establishing a new standard of trust in the industry.

In processing plants, collaborative and autonomous robots are taking over repetitive and high-precision tasks, improving efficiency and reducing occupational hazards. These systems ensure product consistency and enable 24/7 operations, increasing productivity without compromising quality.

Although still in its early stages, 3D food printing is unlocking extraordinary possibilities for personalised nutrition. This technology allows for the creation of products tailored to specific dietary needs, with significant implications for hospital, sports, and geriatric nutrition, while also inspiring innovative chefs to explore new gastronomic frontiers.

Success Stories: Transformation in Action

Digital transformation is already having a tangible impact on food companies across different specialisms and geographies.

A striking example is Avebe, a Dutch cooperative specialising in starch potato cultivation, which has completely overhauled its technological infrastructure by implementing SAP ECC to unify all critical processes. This centralised platform enables real-time management of everything from finance to general administration, empowering better decision-making. For this ambitious transformation, Avebe partnered with CTAC, a technology consultancy and member of United VARs, a global alliance of SAP partners.

In Germany, AZO, a manufacturer specialising in automated systems for handling food raw materials, has taken a major step towards digitalising its services. The company developed myAZOplus, an innovative portal based on SAP Commerce Cloud, which has revolutionised how customers access information and services related to their production equipment. As Thomas Steinbach, CIO of AZO, highlights, this platform has fundamentally transformed customer relationships, significantly enhancing satisfaction with the support of All for One.

Meanwhile, Lunch Garden, Belgium’s largest restaurant chain, has made digitalisation a cornerstone of its growth strategy towards 2025. With a clear vision for the future, the company has formed a strategic alliance with SAP as a software provider, Amazon Web Services (AWS) as its cloud platform, and Ctac as a consulting partner.

By implementing SAP S/4HANA in the cloud, Lunch Garden has centralised and optimised all business processes, enabling it to evolve into a more agile, digitally-driven organisation that is better positioned to deliver superior customer experiences and confidently navigate future challenges.

Pending Challenges on the Digital Horizon

Despite the immense potential of digitalisation, the food sector faces critical challenges that require strategic attention. The implementation of advanced technologies demands a highly skilled workforce, a particularly scarce resource among small and medium-sized enterprises.

Continuous training and upskilling in digital competencies have become crucial to ensuring that these innovations benefit the entire industry, rather than remaining the exclusive domain of large corporations.

The increasing interconnection of production systems also heightens vulnerability to cyberattacks, threatening not only business continuity but potentially food safety as well. Any digitalisation strategy must therefore incorporate robust cybersecurity measures tailored to the specific needs of the sector.

Furthermore, the growing use of digital technologies brings increased energy consumption, raising concerns about the true environmental impact of this transformation. The challenge lies in balancing innovation with sustainability—leveraging digitalisation to optimise resource efficiency and reduce overall ecological footprints.

Another significant challenge is the inherent tension between consumer demands for greater transparency and companies’ need to protect sensitive information about their processes and formulations. Striking the right balance between openness and safeguarding corporate knowledge requires innovative, context-specific solutions.

More Transparency and Sustainability

The digital transformation of the food sector is not merely a matter of technological modernisation; it represents a fundamental redefinition of our relationship with food.

Emerging technologies offer a unique opportunity to build a more transparent, efficient food system that is better equipped to tackle global challenges.

In a world where food safety, sustainability, and personalised nutrition are gaining increasing importance, digital tools are becoming indispensable allies in an industry as vital as food production.

The future holds not only greater efficiency in food production but also a new era of collaboration between producers and consumers, united by transparent information flows that are reshaping food culture.

This revolution has only just begun, and its impact promises to be as transformative as it is nourishing for generations to come.