Microfactories: The Future of Production is Here

From recycled homes to personalised fashion, a new industrial model is taking shape—driven by innovation, responding to local needs, and reshaping global supply chains.For over a century, industrial might was measured in square metres and endless assembly lines. Today, that paradigm is beginning to shift. Large-scale production is giving way to a new generation of factories: small, automated, and designed to operate close to consumers.

Microfactories combine flexibility, speed, and sustainability in compact spaces that defy the traditional rules of manufacturing. Rather than mass production, they aim for intelligent production: responding to real demand, reducing logistical lead times, and minimising the environmental footprint.

A new industrial model is beginning to take hold, driven by technological innovation and the need to adapt to an ever-changing world.

The Technological Engine of Microfactories

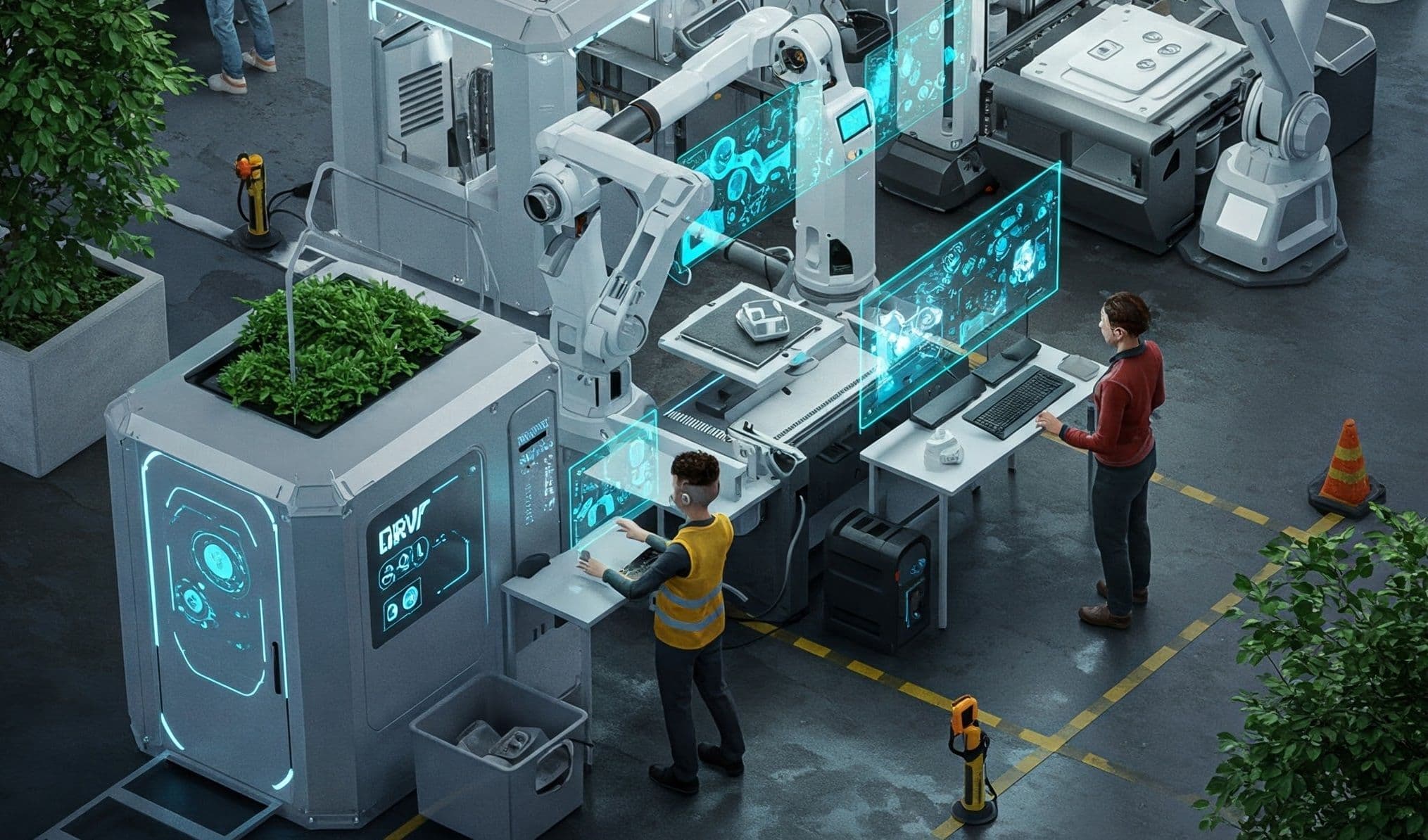

The rise of microfactories is not merely a response to a change in scale but a result of profound technological transformation. Unlike traditional plants, these compact units harness a suite of innovations that are redefining how products are made.

One of the key technologies is industrial 3D printing, which enables the direct creation of parts from digital models, eliminating the need for large inventories and facilitating customisation on a previously unimaginable scale.

Collaborative robotics, meanwhile, introduces robots that work alongside human operators, automating tasks flexibly within confined spaces and without the heavy infrastructure demands of classic assembly lines.

Artificial intelligence also plays a central role, driving everything from process monitoring to fault prediction and dynamic production optimisation, enabling microfactories to respond in real time to variations in demand.

Added to this is the Internet of Things (IoT), which connects sensors, machines, and management systems, ensuring precise operational control and enhanced energy efficiency.

Finally, cloud-based manufacturing software enables the design, programming, and management of production from accessible and synchronised digital platforms, making it feasible for different microfactories to operate as agile nodes within the same productive network.

These technologies not only facilitate operation with lower costs and shorter turnaround times but also open the door to a new industrial logic: closer to the customer, more adaptive, and far more environmentally conscious.

Advantages of a New Way of Producing

The microfactory model offers advantages that go well beyond simple space saving. In an industrial environment where speed, flexibility, and sustainability are increasingly critical, these small production units unlock new strategic opportunities for businesses. One of their main strengths is the ability to adapt rapidly to market changes.

By working with small batches and on-demand production, microfactories enable the launch of new products, the modification of designs, or rapid responses to fluctuations without the rigidity of large assembly lines.

This agility translates into a crucial competitive advantage in sectors where continuous innovation is the norm.

Another major benefit is the ability to bring production closer to consumer markets. By installing microfactories in strategic locations, companies can reduce logistical costs, shorten delivery times, and offer a more personalised response to local needs.

This decentralisation also enhances supply chain resilience, minimising the impact of global disruptions. From an environmental perspective, the model supports more sustainable manufacturing.

The use of precision technologies, the optimisation of material and energy consumption, and localised production significantly reduce the carbon footprint, aligning businesses with increasing social and regulatory demands for environmental responsibility.

Finally, microfactories democratise access to industrial production. By requiring lower initial investments and offering scalable models, they open the door to a new generation of entrepreneurs, start-ups, and small businesses previously excluded from the traditional manufacturing ecosystem.

Examples Setting the Trend

Microfactories are no longer a futuristic promise; they are a tangible reality across a range of industries worldwide.

In Phoenix, Arizona, a pioneering microfactory dedicated to plastic recycling has been inaugurated. This facility converts local plastic waste into useful products such as furniture and construction materials, processing between 500 and 1,000 tonnes of plastic per year.

In the household appliance sector, GE Appliances has implemented microfactories such as FirstBuild in Louisville, Kentucky, and CoCreate in Stamford, Connecticut. These facilities enable the agile production of small batches of innovative products, facilitating rapid market validation before scaling up to mass production.

In the construction sector, the British start-up AUAR, in collaboration with ABB Robotics, is developing robotic microfactories for the manufacture of sustainable timber housing. These facilities use a single type of material and machinery, simplifying the supply chain and reducing construction costs.

Mighty Buildings has established microfactories in locations such as Monterrey, Mexico, for the production of 3D-printed homes. These houses, built with recycled materials and designed to be energy-efficient, can be assembled in as little as three days, offering an innovative solution to the housing crisis.

Companies like Arrival are demonstrating that it is possible to produce electric vehicles in decentralised and highly automated facilities, significantly reducing production costs and lead times.

In the textile sector, initiatives such as Rodinia Generation are revolutionising fashion by implementing microfactories that enable on-demand production, eliminating the use of water and toxic chemicals.

Finally, ChopValue has developed a network of microfactories that transform discarded bamboo chopsticks into high-value products such as furniture and decorative surfaces. With operations in various cities, this company exemplifies how microfactories can foster the circular economy at a local level.

The Future of Manufacturing is Already Underway

Microfactories are far more than a passing trend: they are shaping the immediate future of the manufacturing industry.

Their ability to adapt rapidly to market demands, reduce environmental impact, and foster local economies positions them as fundamental pillars in the transition towards more sustainable and efficient production models.

Moreover, the concept of microfactories aligns perfectly with the circular economy, promoting the reuse of materials and the reduction of waste.

This not only benefits the environment but also offers companies a competitive advantage by responding to growing consumer demands for sustainability.

As we move towards an era where customisation, efficiency, and sustainability are key, microfactories are emerging as a comprehensive solution.

Their implementation not only transforms how we produce but also redefines supply chains and the relationship between manufacturers and consumers.