Industry 4.0: Innovation and Sustainability in the Digital Age

From smart factories to real-time decision-making, explore how businesses are harnessing technology to transform operations and customer experiences.The business world is undergoing an unprecedented revolution. The days of rigid, disconnected production chains are a thing of the past.

Today, digitalisation and the convergence of advanced technologies are transforming industry into an interconnected and intelligent ecosystem.

This new era, known as Industry 4.0, is not only redefining the way companies operate but also setting new standards for future competitiveness.

The Fourth Revolution

Industry 4.0 represents the Fourth Industrial Revolution, marking a definitive shift in technological evolution.

While the First Revolution was powered by steam engines, the Second by electrification, and the Third by computing and the Internet, the current revolution is defined by the fusion of digital, physical, and biological technologies.

Concepts such as the Internet of Things (IoT), artificial intelligence (AI), big data, advanced robotics, and blockchain are no longer emerging trends; they are foundational pillars for building more agile, efficient, and sustainable factories.

Forging a New Paradigm

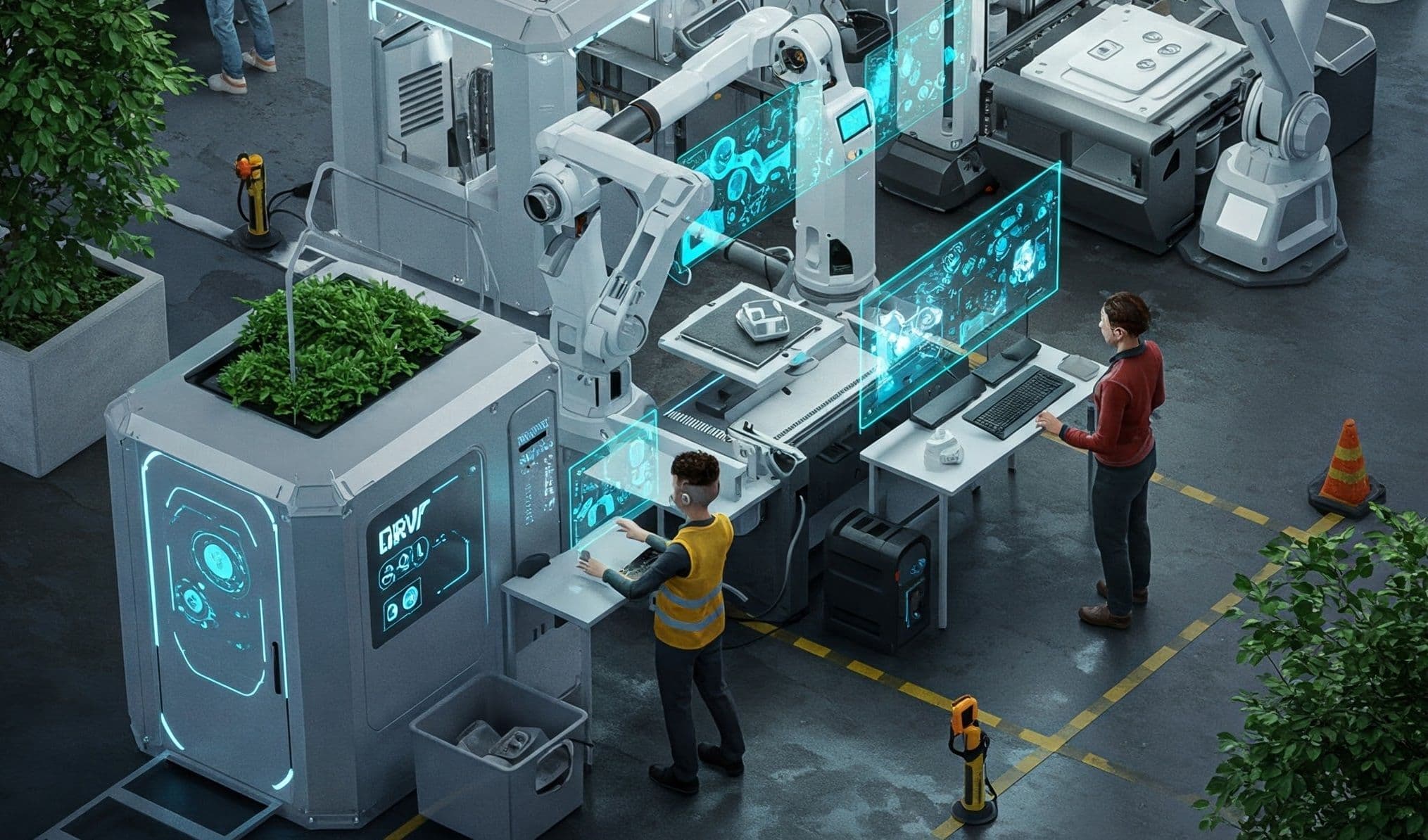

A study by IDC predicts that global spending on digital transformation will reach $3.9 trillion by 2027, highlighting the scale of this technological shift. In this interconnected ecosystem, devices and systems not only work but think.

Using intelligent sensors and advanced algorithms, companies can analyse real-time data to anticipate problems, optimise processes, and minimise waste.

These technologies enable businesses to enhance operational efficiency and decision-making. By centralising and analysing data, organisations gain comprehensive oversight of their supply chains, ensuring greater transparency and the ability to anticipate and resolve issues swiftly.

Industry 4.0 is also transforming the relationship between businesses and their customers. The capacity to customise products and services enables companies to meet specific consumer demands, delivering an increasingly tailored and satisfying experience.

Moreover, the emphasis on sustainability is at the heart of this transformation. By digitising production processes, organisations are reducing their carbon footprints, optimising material and energy usage, and minimising waste.

These measures not only enhance environmental stewardship but also contribute to cost efficiency and long-term viability.

The Transformation of Patatas Meléndez

A compelling example of this evolution is the transformation of Patatas Meléndez, a leading Spanish potato producer that commands 20% of the national market.

Tasked with building a modern plant equipped with Industry 4.0 functionalities, the company embraced RISE with SAP, an integrated solution encompassing production, materials management, sales, analytical accounting, product costing, and logistics.

The project was expertly led by SEIDOR, an SAP technology partner and member of United VARs, which played a pivotal role in designing and implementing the solution.

The key to the transformation’s success lay in adopting SAP DataSphere and SAP Analytics Cloud. These tools enabled the integration and centralisation of information from the plant’s manufacturing execution systems (MES) within a unified environment.

Sergio Calvo, CIO of Patatas Meléndez, highlighted the impact: “This implementation not only connected SAP databases but also integrated the plant's MES systems, achieving real-time data analysis”.

This capability has significantly enhanced manufacturing speed, improved the quality control of final products, and enabled faster, data-driven decision-making.

A Strategic Imperative

The success of Patatas Meléndez demonstrates how a well-executed strategy can transform a traditional operation, elevating it to a new level of innovation and efficiency. However, the journey is not without challenges.

Organisations seeking to adopt Industry 4.0 must navigate budgetary constraints, the threat of cyberattacks, and the ever-evolving nature of technology, which demands continuous system updates.

Additionally, this transformation involves a cultural shift within organisations. Preparing the workforce for future roles is crucial to ensuring a smooth transition and fostering an innovation-ready environment.

Despite these challenges, Industry 4.0 offers a unique opportunity for businesses aiming to remain competitive in an increasingly demanding global market. By embracing this revolution with a proactive and collaborative approach, companies can secure long-term sustainability and position themselves as leaders in shaping the future.

Far from being optional, digital transformation has become a strategic imperative—one that defines the path to survival and success in the modern industrial landscape.