Exoskeletons for a Safer Labour Future

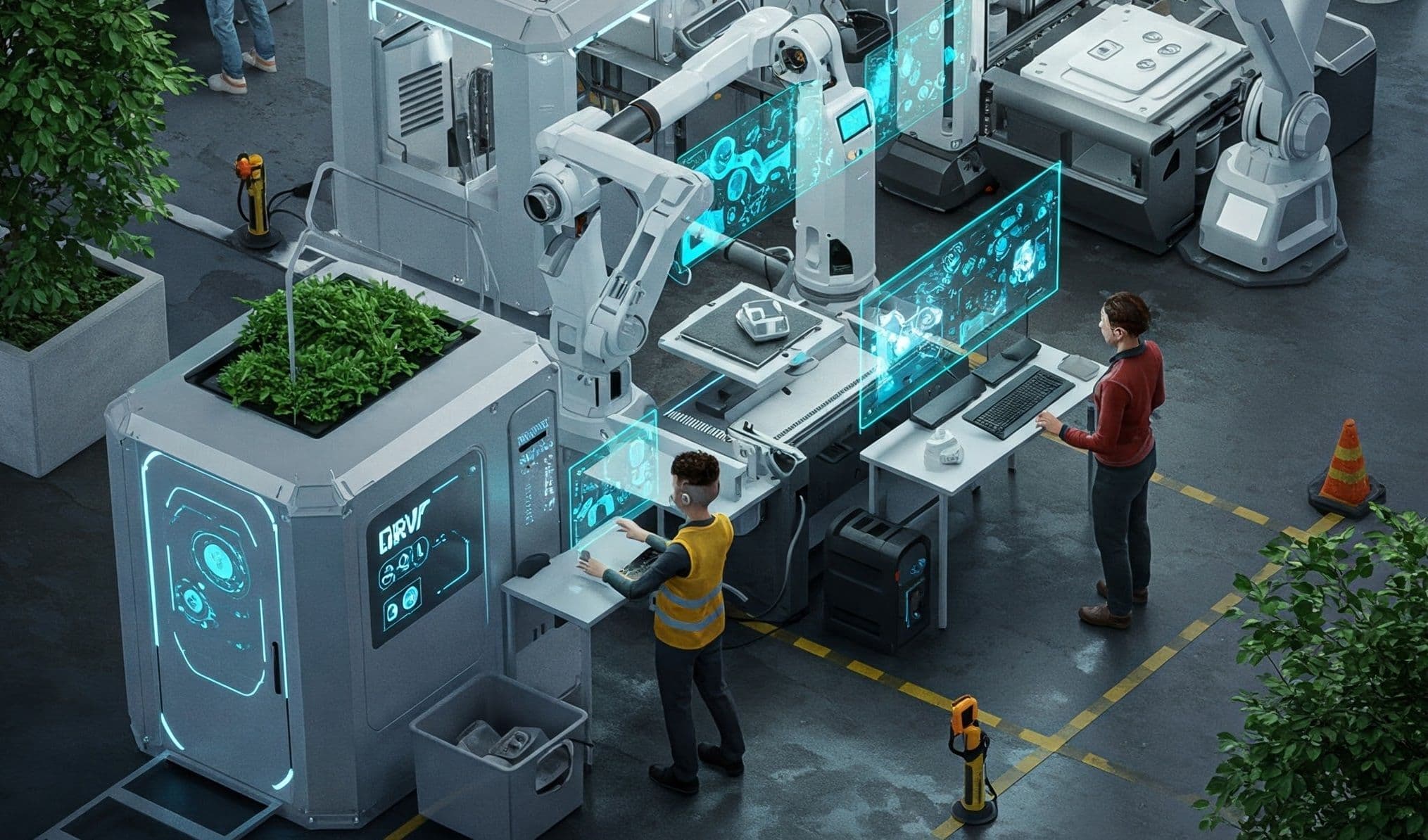

This technology is ushering in a new era of physical work, helping to prevent injuries and boost productivity in key sectors such as manufacturing, healthcare, and construction. The future of physical work no longer relies solely on human strength.Industrial exoskeletons, portable devices designed to provide mechanical support and reduce strain on the body, are revolutionising ergonomics in industries like manufacturing, logistics, and construction.

These devices can be passive, using spring systems and high-performance materials to redistribute load, or active, incorporating motors and sensors to amplify the user’s movements.

The concept of exoskeletons is not new. Their development dates back to the 1960s, when they were initially explored for military purposes. However, in recent years, the technology has advanced significantly, enabling their integration into industrial environments.

A Growing Market

The global industrial exoskeletons market is expanding rapidly. According to a report by Mordor Intelligence, it is estimated to reach £1.5 billion by 2030, with a compound annual growth rate (CAGR) of 15.32% between 2025 and 2030.

This growth is driven by increasing musculoskeletal injuries in work environments, the need for robotic rehabilitation, and advances in assistive technologies.

The report indicates that the growing adoption of exoskeletons in manufacturing and logistics is accelerating their integration, thanks to improvements in mobility, ergonomics, and energy efficiency.

However, the report also highlights the lack of clear regulations and high initial costs, factors that could hinder the mass adoption of these devices in industry.

Reducing Risks

Musculoskeletal injuries have historically been one of the greatest challenges in industrial environments.

Repetitive movements, lifting heavy loads, and prolonged postures contribute to ailments that affect both worker health and company costs. Exoskeletons, by reducing physical effort and improving posture, are significantly mitigating these risks.

Major automobile manufacturers have integrated these devices into their production lines, yielding positive results in both employee wellbeing, reducing injuries, and operational efficiency.

In construction, exoskeletons help workers to sustain heavy tools for extended periods, reducing fatigue and improving work precision.

In manufacturing, they facilitate repetitive tasks such as assembly and welding, reducing the risk of chronic injuries.

In logistics, they enable workers to lift and transport loads more efficiently, reducing the risk of lower back injuries.

Health and Rehabilitation

Exoskeletons have also revolutionised healthcare and rehabilitation, offering an innovative solution for patients with reduced mobility and neuromuscular disorders.

These devices, used in rehabilitation therapies for patients with spinal cord injuries, strokes, or degenerative diseases, assist in recovering movement capacity and strengthening muscles through robotic assistance.

Recent studies have demonstrated that their use in clinical environments not only improves patient autonomy but also reduces the burden on physiotherapists.

Moreover, for people with disabilities, exoskeletons are opening new possibilities for inclusion, offering them the opportunity to regain independence in daily life. From models designed for walking to more advanced versions assisting in precision tasks, this technology is redefining accessibility and quality of life.

The integration of artificial intelligence in this technology has further enhanced rehabilitation and disability assistance. Thanks to advanced algorithms and state-of-the-art sensors, these devices can dynamically adapt to the user’s movements, adjusting assistance levels according to their real-time progress.

This is especially valuable in rehabilitation therapies for patients with spinal cord injuries or neuromuscular diseases, as it allows for more personalised and efficient treatment.

Additionally, AI optimises energy consumption, extending exoskeleton usage without compromising performance, and enhances safety by detecting and preventing falls or unstable movements.

Technology with Potential

The industrial exoskeletons market is thriving, transforming how we view physical work.

As this technology advances, it is not only reducing injuries and improving workplace efficiency but also expanding the boundaries of human capability.

What was once a futuristic idea is now helping improve the health, safety, and productivity of workers in key sectors.

Exoskeletons represent more than just a technological innovation: they are a turning point in our relationship with work and disability. Their evolution suggests a future where technology doesn’t replace humans but empowers them.

In the coming years, we will see a convergence of artificial intelligence, robotics, and biomechanics that will redefine the limits of human capacity. Exoskeletons will likely become as commonplace as smartphones, naturally integrating into work, medical, and everyday environments.

The true revolution will not be technological, but cultural: learning to view these devices not as external tools, but as natural extensions of our physical and cognitive abilities.