Cobots are transforming industry

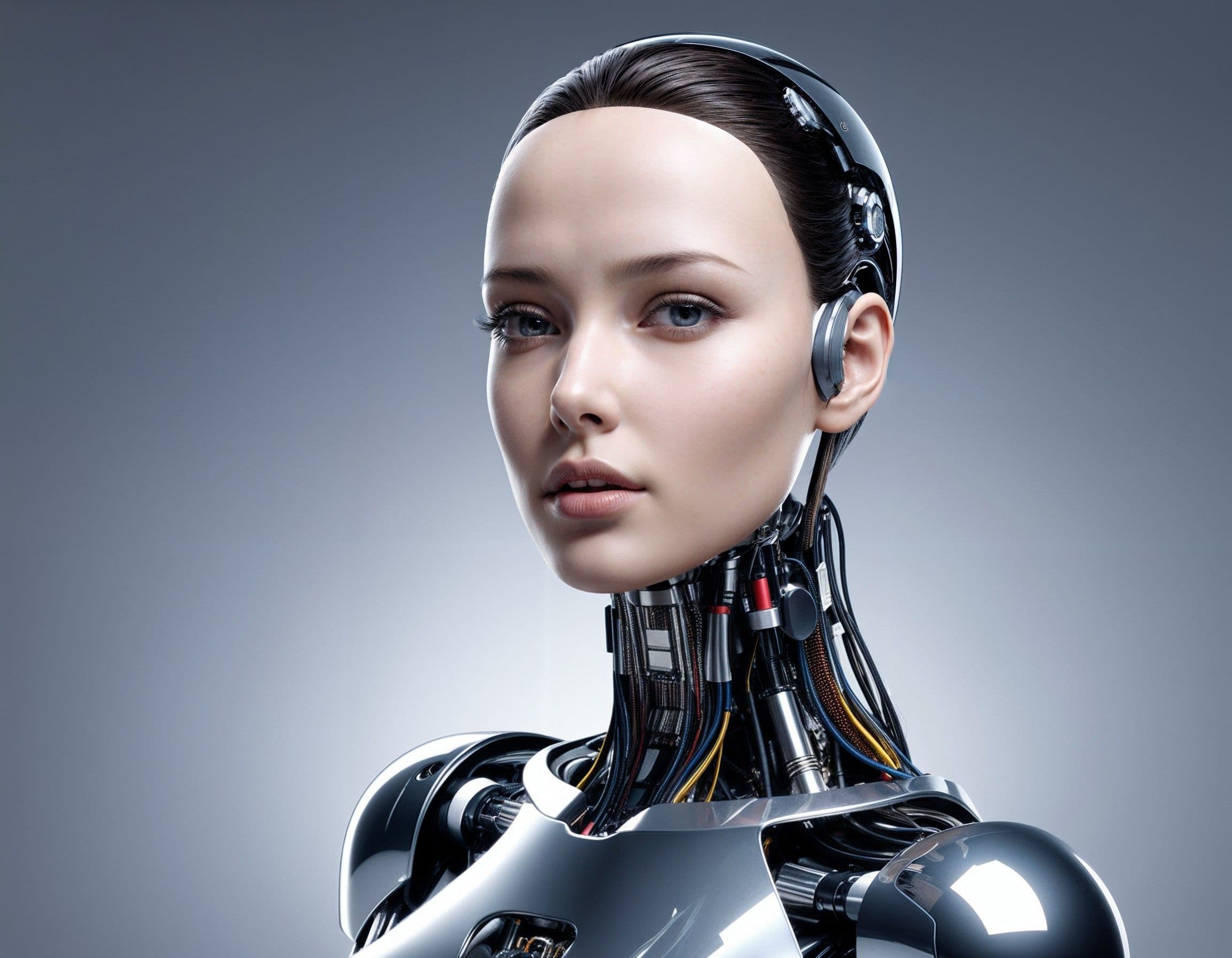

These collaborative robots work alongside humans safely and efficiently. Their versatility enhances production across various sectors, from manufacturing to healthcare. Despite some challenges, their easy integration and economic accessibility make them a key tool for the future of automation.In an operating theatre, a surgeon and a robot work together with astonishing precision to save a critically ill patient. This isn't a scene from a futuristic film but a reality showcasing the potential of collaborative robotics.

The influence of robots in healthcare is expanding, from performing surgeries to assisting in complex diagnostics and handling medications.

Yet their impact extends beyond healthcare, reaching all sectors of the economy. In factories, shops, offices, and other businesses, collaborative robots are transforming the way we work, proving that collaboration between humans and machines can be both efficient and innovative.

Now, what is collaborative robotics, and how does it work? It's an emerging field that combines the dexterity of robots with human intelligence, increasingly used by organisations looking to enhance their production processes.

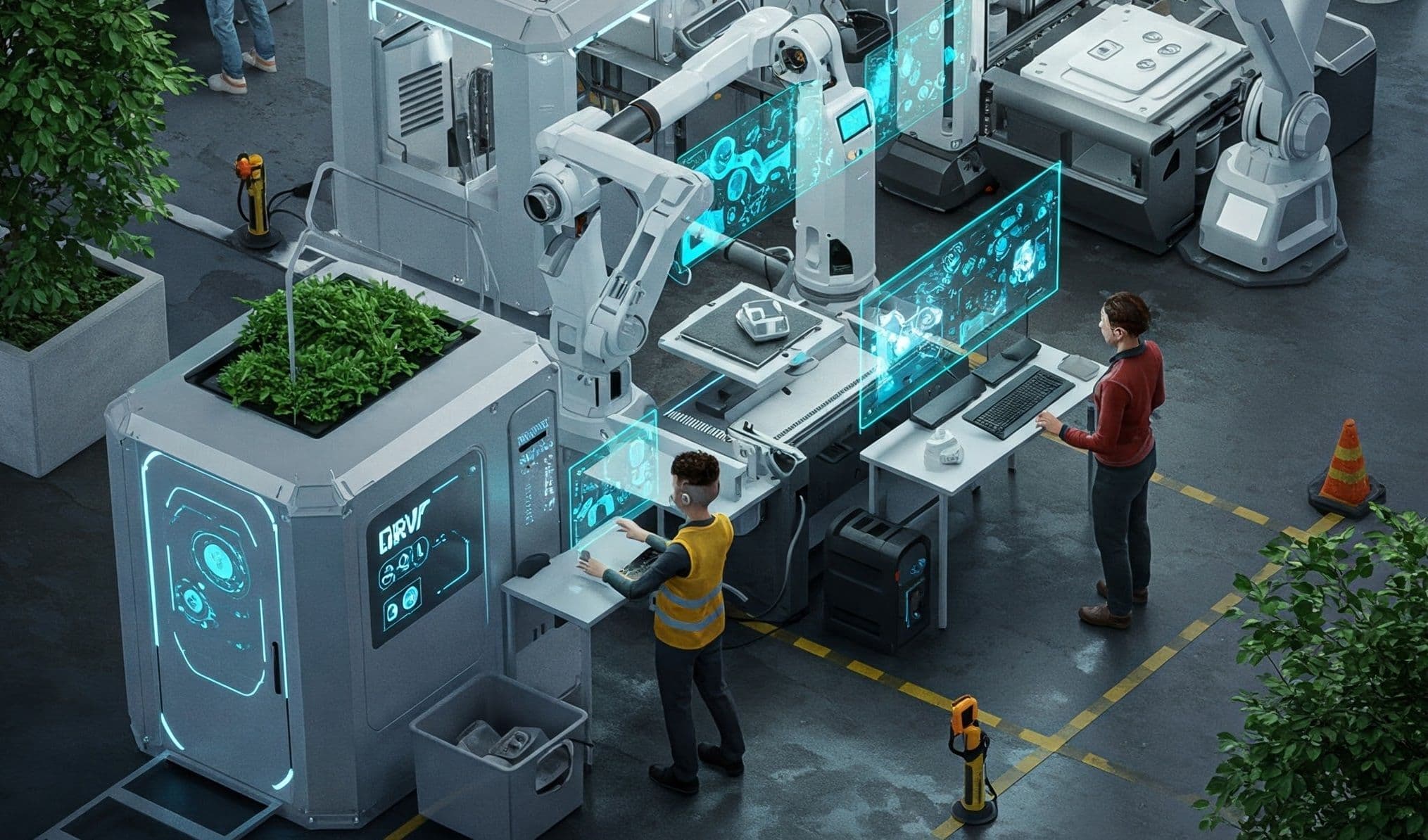

Unlike traditional robots, which were isolated machines confined to safety cages, collaborative robots—known as cobots—are designed to work alongside humans, sharing spaces and tasks in full cooperation.

"Cobots can be quickly integrated into existing production lines and work in harmony with traditional industrial robots, without requiring significant workflow changes. They are compact and space-efficient, a great advantage when space is limited", says robotics expert Spacey Moser, CCO of Universal Robots.

The adoption of cobots is a growing trend. According to a study by Interact Analysis, the global collaborative robot market exceeded $1 billion in revenue in 2023, with growth expected to be around 22% in 2024.

The consultancy also forecasts that this market will grow by an average of 20% annually until 2028.

"The global cobot market is maturing as end users seek holistic solutions rather than merely purchasing large equipment," says Maya Xiao, research manager at Interact Analysis.

This shift towards holistic solutions reflects companies' long-term thinking, focusing on the versatility of their tools rather than solely on acquiring high-tech hardware.

The Era of Collaborative Robots

Cobots emerged in the mid-1990s as an innovative solution to integrate automation in environments where safe interaction between humans and robots was essential. The term was coined in 1996 by J. Edward Colgate and Michael Peshkin, two mechanical engineering professors at Northwestern University, who led the development of the first cobot, supported by General Motors.

Initially, these machines were passive mechanisms, assisting in the movement of parts and objects by following human operators' motions, but they couldn’t move autonomously.

Over time, they evolved with the incorporation of motors, actuators, and advanced sensors, alongside AI and machine learning systems. These improvements enabled cobots to perform more complex, autonomous tasks while maintaining a safe environment for human workers. Today, they are a key component of modern industry.

Safety is paramount in cobot design. Equipped with advanced sensors, cobots detect human presence and adjust their behaviour instantly to avoid collisions.

One of the most notable features of cobots is their user-friendly nature. Their intuitive interfaces mean that advanced programming knowledge isn’t required, democratising access to robotics and enabling companies of all sizes to implement automated solutions.

Cobots are also highly versatile and portable. Their compact, lightweight design allows them to be moved easily between workstations and adapt to changing production needs.

Not only can cobots perform programmed tasks, but they also have the ability to learn and adapt. Thanks to AI and machine learning systems, they improve performance over time and adjust to changes in their working environment.

They also maintain high accuracy in repetitive tasks, improving product quality and reducing errors. Their integration into existing workflows is simple, as they fit into production lines without the need for extensive workspace redesign.

Lastly, their economic appeal is a crucial factor. With a lower price point than traditional industrial robots, cobots offer an attractive return on investment, particularly for small and medium-sized enterprises seeking automation without prohibitive costs.

Versatility and Challenges

Cobots have proven their versatility across a wide range of industries. In manufacturing, they are effectively used on assembly lines to optimise production. In logistics, they manage inventory and automate warehouse tasks.

DHL, for instance, has introduced robots in several distribution centres, achieving up to a 60% improvement in some packaging processes.

In healthcare, cobots assist in surgeries, physical rehabilitation, and patient care. In automotive manufacturing, they work alongside operators to assemble precision components and conduct quality inspections.

BMW is a notable success story, having implemented cobots on its production lines, improving quality and reducing assembly times.

In agriculture, cobots are deployed for harvesting, crop management, and livestock care. Equipped with sensors and vision systems, they enhance productivity and sustainability in farming operations.

However, despite significant progress, widespread cobot adoption faces several critical challenges. The absence of clear regulatory frameworks is a major issue.

As cobots become integral to work environments, specific regulations are needed to govern their use, ensure safety, and establish quality standards.

Worker resistance to change also poses a significant hurdle. Fears of job displacement due to automation are real and can lead to resistance and workplace tensions.

Cybersecurity is another growing concern. As cobots become more connected and reliant on AI, the risk of cyberattacks and vulnerabilities increases.

Addressing these challenges will require cooperation between manufacturers, lawmakers, educators, and businesses.

A Promising Future

Organisations that wish to capitalise on the potential of cobots must work with technology partners who understand both business needs and technological capabilities.

Tailored solutions and expert support are essential to ensure the successful implementation of collaborative robotics, minimising risks and maximising benefits.

The future of collaborative robotics is promising. With AI continuing to advance and the demand for automation on the rise, cobots are set to play an increasingly vital role in global industry.

Companies that adopt this technology will not only enhance their competitiveness but also position themselves at the forefront of the industrial revolution reshaping the future of work.